Thermal conductivity of stainless steel

What is thermal conductivity?

Thermal conductivity λ is a measure of how well a material transports heat (i.e. thermal energy) by means of heat conduction. The lower the value of thermal conductivity, the better the thermal insulation. The thermal conductivity in the SI system has the unit Watt per meter and Kelvin (W/m⋅K). Materials with high electrical conductivity also tend to have a high thermal conductivity and vice versa. Exceptions confirm as always the rule. For example diamond has a very high thermal conductivity of λ=2000 W/m⋅K.

What is thermal conductivity important for in constructions?

In building constructions, the thermal conductivity in the area of "normal" ambient temperatures is particularly important for the thermal insulation of buildings, in which, of course, poorly conductive, i.e. insulating materials are chosen for the building envelope. It is also important regarding the constructive fire protection and has to be considered in the fire design of members within a temperature range of usually 20°C to 1200°C. The background is that the fire resistance is based on a specific fire room curve, the so-called ISO standard fire.

Which code defines the thermal conductivity of stainless steel?

The thermal and mechanical material properties of the stainless steel grades 1.4301, 1.4401, 1.4571, 4.4003 and 1.4462 can be found in EN 1993-1-2, informative Annex C.

Why does stainless steel behave much more favourable than structural steel in the event of a fire?

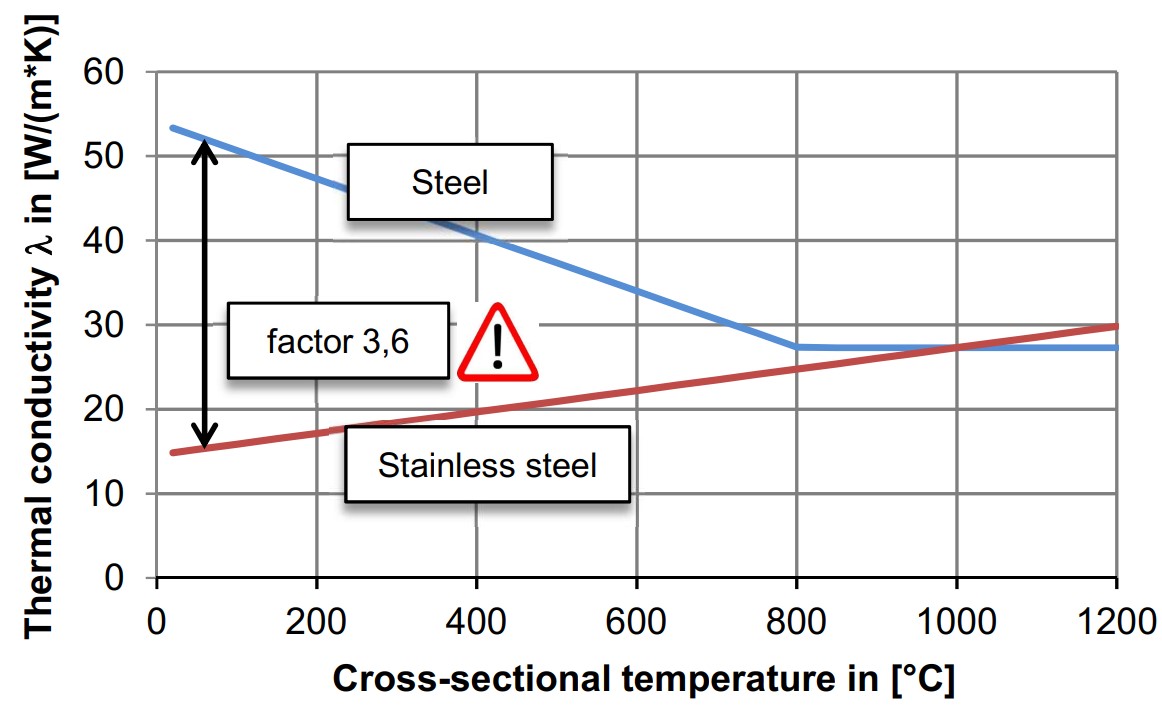

The figure compares the thermal conductivity λ of structural steel and stainless steel in the high temperature range from 20°C to 1200°C. It becomes clear that the thermal conductivity of stainless steel is significantly lower than that of the structural steel for temperatures less than 1000°C. In this respect, members made of stainless steel, such as columns, heat much more slowly than those made of structural steel. Since stainless steel also has much more favourable mechanical properties than structural steel in the event of a fire, it is very worthwhile to prove members using a fire design.

How I can help you.

I can offer you a short-term fire design for your given task in the European Union or worldwide. The documentation contains the essential information on the heating of the cross-section, the fire resistance of the member or structure as well as its deformations. We can of course provide further services so do not hesitate to contact me.

What are your benefits?

My clients often save costs by using sophisticated fire design. In the case of new buildings, leaner and therefore more economical constructions can be carried out. In the case of existing structures extensive upgrading measures can often be avoided by an accurate fire design.

My initial consultation for your project

To clarify your specific task, it is best to call me. Or you can send me an e-mail with some key data. On this basis, we can discuss the framework conditions and I can create an attractive offer for you.