Fire-exposed steel

Fire behaviour of steel

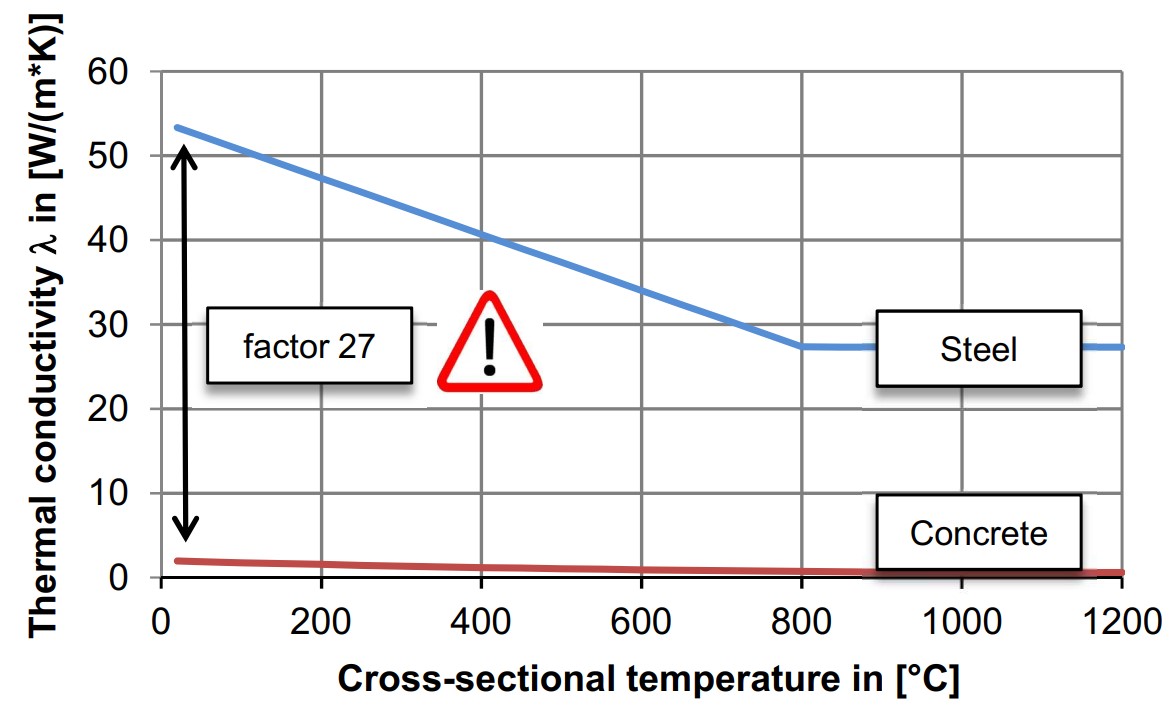

In the event of a fire, unprotected steel members fail after approximately 15 to 20 minutes under normal load utilization. This is due to its high thermal conductivity, resulting in quick heating of the steel cross-section. Compared to reinforced concrete with λ=2-3 W/(m*K), carbon steel has with λ=50 W/(m*K) an approximately 25-fold higher thermal conductivity.

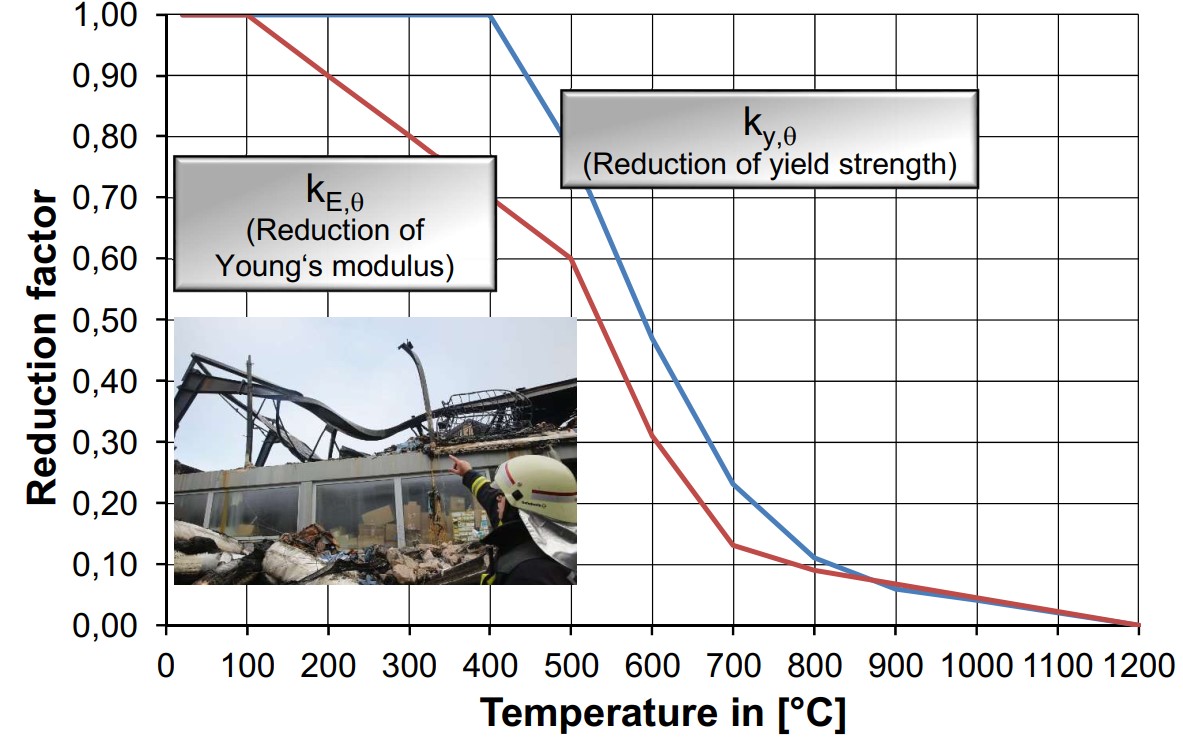

Due to the rapid heating the yield strength and the modulus of elasticity of structural steel decrease in the event of a fire very quickly. Due to the increasing deformation, this leads either to cross-sectional failure (due to the reduction of the yield strength) or to stability failure (global or local buckling due to the reduction of the modulus of elasticity).

Structural fire design according to Eurocodes

The thermal and mechanical material characteristics of fire-exposed structural steel can be found in EN 1993-1-2. The Eurocodes ending with "-1-2" are also called the "hot" Eurocodes because they deal with the material characteristics of concrete (EN 1992-1-2), structural steel (EN 1993-1-2), steel composite construction (EN 1994-1-2) and wood (EN 1995-1-2).

These material laws are stored in special programs for the fire design of members. The programs use the thermal material properties in the thermal analysis, while they use the mechanical material characteristics for mechanical analysis.

Thermal material properties of fire-exposed steel

Thermal elongation

The thermal elongation of structural steel Δl/l depends on the cross-sectional temperature θa according to EN 1993-1-2 (2010):

- from 20°C ≤ θa < 750°C: Δl/l = 1,2*10-5 * θa + 0,4*10-8 * θa2 - 2,416*10-4

- from 750°C < θa ≤ 860°C: Δ l/l = 1,1*10-2

- from 860°C < θa ≤ 1200°C: Δl/l = 2*10-5 * θa - 6,2*10-3 * θa

Thermal conductivity

The thermal conductivity of structural steel λa in W/(m*K) depends on the cross-sectional steel temperature θa and is defined as follows in EN 1993-1-2 (2010):

- from 20°C ≤ θa < 800°C: λa = 54 - 3,33*10-2 * θa

- from 800°C ≤ θa ≤ 1200°C: λa = 27,3 * θa

Specific heat capacity

The specific heat capacity is a measure how much energy is needed (in Joule) to heat a mass of 1 kg structural to 1°C. The specific heat capacity of structural steel ca in J/(kg*K) depends on the cross-sectional steel temperature θa as defined in EN 1993-1-2 (2010):

- from 20°C ≤ θa < 600°C: ca = 425 + 7,73*10-1 * θa - 1,69*10-3 * θa2 + 2,22*10-6 * θa3

- from 600°C ≤ θa < 735°C: ca = 666 + 13002÷(738 - θa)

- from 735°C ≤ θa < 900°C: ca = 545 + 17820÷(θa - 731)

- from 900°C ≤ θa ≤ 1200°C: ca = 650

Densitiy of structural steel

According to EN 1993-1-2 (2010 version), it can be assumed that the raw density ρa = 7850 kg/m3 of structural steel is independent of the temperature.

Mechanical material properties of fire-exposed structural steel

Yield strength

From a temperature of 400°C, the yield strength of structural steel drops rapidly. The temperature-dependent reduction factor ky,θ for the yield strength fy,θ can be found in the diagram below.

Young's modulus

The Young's modulus of structural steel also depends on the temperature. The Young's modulus of structural steel decreases from 100°C so that heated structures are endangered by stability problems. In the diagram below, the reduction factor kE,θ for the Young's modulus is plotted against the cross-sectional temperature.

How I can help you.

I can offer you a short-term fire design for your given task in the European Union or worldwide. The documentation contains the essential information on the heating of the cross-section, the fire resistance of the member or structure as well as its deformations. We can of course provide further services so do not hesitate to contact me.

What are your benefits?

Our clients often save costs by using sophisticated fire design. In the case of new buildings, leaner and therefore more economical constructions can be carried out. In the case of existing structures extensive upgrading measures can often be avoided by an accurate fire design.

My initial consultation for your project

To clarify your specific task, it is best to call me. Or you can send me an e-mail with some key data. On this basis, we can discuss the framework conditions and I can create an attractive offer for you.